Understanding Testing of Gasoline Direct Injectors

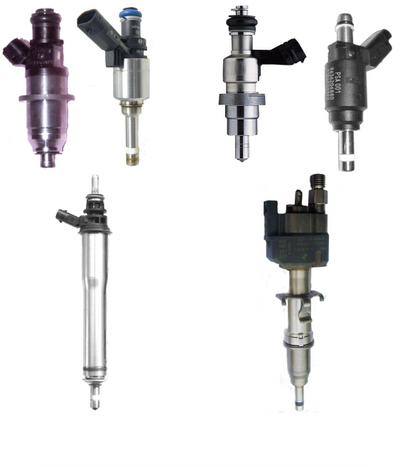

GDI Introduction

GDI or Gasoline Direct Injection is new to some. Some love it, some hate it but no matter what, Direct Injection for Gasoline engines is here to stay.

There are many different manufacturers’ names for GDI, but they all have the same feature; DIRECT INJECTION FOR A GASOLINE ENGINE.

The advantages it offers not only to the motorist but also the vehicle manufacturers, means there will never be a return to the original manifold/port injection systems.

GDI as we know it now has been in mass production since 1997, when Mitsubishi introduced the Carisma, using Hitachi produced GDI injectors. The initial launch was one of expectations and all the other VM's waited to see the acceptance of this type of engine. Even though most of them had already been working on such systems, they still wanted to see the motorists’ reaction to the GDI vehicle.

The performance and economy were to be the winner and as the car was a family saloon,it appealed perfectly to the family man who wanted both. The die was cast, and the exposure was good to start with. Any initial problems with the system were credited to teething problems caused by the fuel quality in the UK which was leaving deposits in the combustion chamber and this was having an adverse effect on the engine's all round performance, although that was not generally known at the time.

Injector Manufacturer Production Testing

The injector manufacturers like Bosch and Denso design and produce injectors to work at high pressure and during production they test the injectors at pressures over and beyond the operating pressure the system will operate at to ensure they are can perform correctly and are safe for extreme use while remaining within the tolerance they require.

In addition, the injectors are checked for leaks, not only from the valve seat but also from the body and around the electrical connectors. Any leaks in these areas are not acceptable in any form but the chances of this happening are extremely remote but must be tested during production all the same.

All injectors initially produced by the manufacturers have already undertaken and passed a full range of endurance tests before they are accepted for production.

Vehicle Manufacturer Production Line & Warranty Injector Testing

Vehicle manufacturer’s production line testing of products in the event of a problem is critical to the whole assembly line of a range of vehicles. Just one failure can halt the line until the reason for the failure has been identified and the problem resolved; whatever the cause.

For the VM’s, should a component be found to be faulty, it could mean all the components in the batch supplied are withdrawn and replaced with a fresh batch. Should additional components found to be faulty, then the whole batch are returned to the manufacturer for replacement and in some cases a penalty is imposed on the component supplier.

Even worse is when a component is found to be faulty once the vehicles have been produced and sold into the market and then begins to fail in daily use. The manufacturer has several options to correct it with the worst-case scenario being to recall all the vehicles fitted with that batch of faulty components and replace them, with costs soaring and penalties increasing.

Low Pressure GDI and Vehicle Manufacturer Production Line Testing

Out of car bench testing is being used by several VM’s on their production line test facilities for both port/manifold and direct injection engines. For the VM to pull an engine with a problem from the production line is simple, but to quickly find the cause of the problem and confirm whether the problem is limited to that one engine or could be a problem for all of them is paramount to the whole assembly line.

CFIS’s test machine has been used by various VM’s for a number of years as a quick and easy answer to confirming or eliminating the injector/injectors as a one off or a batch problem. In all cases known they have been a one-off problem, pleasing the production line engineers by saving them valuable down time and money by not having to return the injector to the manufacturer for an analyst report. The training on the use of the system and its user-friendly capabilities allows any of the production line engineers to use the system and act quickly in examining any injector related problems.

Learning About GDI Injectors

Over the years the function of the injector has changed, but not in its basic requirements that is to supply a metered amount of fuel in a specific form ata time and for a duration requested by the vehicles ECU.

Injector changes have been mainly down to meet the emission requirements imposed on the vehicle manufacturers, but it has also been because the vehicle manufacturers while meeting these emission regulations still want to get better engine performance and improved fuel economy out of the vehicle’s engine. Ask any engine tuner and they will tell you that with a manifold injection system, that is an impossible scenario.

In 90% of the motor industry, keeping up to date with changes in technology is beyond most workshop owners’ budget, especially for training and technical updates. Technicians could spend at least 10 working days of a month being trained on the new technology being applied to the different makes of vehicles. The time required would not be cost effective, so they learn from experience by "having a go at it" relying on the equipment they are using to do the job for them or they search the internet technical pages for answers, anyof which are cheaper and more cost effective than sending their staff on training courses.

Most technicians have removed injectors from a port/manifold engine without any major problems. Most are simple and can be removed in 10 minutes to 45 minutes, but some are a bit more time consuming.

Information on these injection systems has always been easy to find and simple to work with when replacing injectors as part of the "diagnosis by replacement" diagnostic test practiced by many workshops around the world.

When it comes to GDI injectors, it's a different scenario due to their location as a direct fit to the combustion chamber. They are not so easy to remove and because of the engineering required for a GDI injector, they are not cheap to replace either. Most are learning about GDI Injectors,but the hard way.

The GDI Injector's Features

The motor repair and service workshops over the past 30 years of working with fuel injection have worked with the basic knowledge of the requirements of the injector, that being how much fuel it delivers. To most, that was the only requirement and for equipment manufacturers to put a machine together to measure the flow of the injectors was simple and cheap.

For the educated technicians, there was more to it than that and the difference in the quality of the workshops repairs and service where injectors were involved was down to the education on the expectations of the injectors and the engine management system together with the equipment being used to carry out these tests and service.

Leak Testing

When testing for leaks, the manufacturers will test at systems pressure, which is how they are tested when new, but experience has shown CFIS that the higher the pressure, the more the pintle is forced in to the seat and any visible evidence of slight wear in the injectors seat is reduced, whereas at a lower pressure, leaks are more evident and visible to the tester.

When injectors returned and checked by the injector manufacturers and are found to be contaminated by poor fuel or covered in carbon that may be interfering with the seating and causing a leak, they can be returned as "No Fault Found".

A weakened or broken pintle return spring inside the injector will not show when high pressure is applied as the pressure again is forcing the valve into the seat, taking over the task of the return spring. In CFIS's opinion and experience, low pressure testing is examining the strength of the internal pintle return spring and gives a more accurate result.

Engine Management Systems

All gasoline vehicles are computer controlled by the Engine Management System (EMS), ensuring the vehicles’ engine performs correctly and efficiently while maintaining the correct emission output. There are a number of features these systems offer for the control and protection of the engine. The ones mentioned here are relevant to the injectors’ performance and operation on a GDI engine.

Fuel Trim Adjustment

The GDI injector has the same basic function of any electronic injector, only now the requirements are far greater and the accuracy much finer. A simple example is the port/manifold injector was working to a 14:1 Air/Fuel Ratio; the GDI injectors are working to a 40:1 ratio and some of the Piezo injectors are working as high as 60:1 ratio.

The loss of any fuel at these levels can and will have an adverse effect on the engine.To counter this, the engine management system has been designed to adjust the "fuel trims" adjusting the fuel delivery to each cylinder to maintain an equal delivery. The fuel trims compensate for the difference in fuel deliveries; they do not correct what has caused the fuel delivery to change. Whatever has caused the change in the fuel will need to be investigated when the problem becomes long-term problem for the system, highlighted by a warning on the dash panel.

Flow Rates

The most important feature of a GDI injector is not the flow rate of the injector butthe fuel distribution and atomization that form the injectors Spray Pattern. CFIS believe that the distribution and atomization of the fuel is 15 times more important than the flow rates. Why 15 times you may ask? CFIS have experienced GDI injectors that have had a difference of up to 15% in flow rates between the best and the worst delivering injector, yet the engine was still running without a problem.

Developments in the Engine Management System now mean it can adjust the flow rate to the individual injector and compensate for any deficiency in the injectors ability to deliver the correct amount of fuel. In theory this is ideal, inpractice it's not. This feature is not correcting the problem, it is compensating for it and although in the short term the vehicle is running fine, in the long term the problem will need to be addressed when the EMS reaches its compensation tolerance level and the engine’s check light comes on.

Spray Patterns - Fuel Distribution and Atomization

How good is that, the vehicles EMS Fuel Trims can adjust individual cylinders so quickly that it can compensate for any differences in the fuel delivery and keep the engine running correctly.

Now let's ask another question. As the injector’s performance deteriorates and the EMS compensates for the lack of flow, how does it measure and compensate for the changes and

deficiencies in the Fuel Distribution and Atomization?

Fact: If you had 6 injectors and 6 different deliveries, with the help of the EMS the engine would run correctly. With 6 different spray patterns and 6 correct deliveries, the engine would run badly.

Fact: If you had 6 injectors and 6 different spray patterns the engine would run poorly and the engine check light would illuminate and if not addressed the EMS would eventually put the engine in "Limp Mode" to protect it from damage.

Fact: The injectors spray pattern is designed with a very specific delivery angles and fuel droplet size. This is to ensure the fuel is directed to the correct location in the combustion chamber with a droplet size that will burn efficiently. Any disruption to the distribution or droplet size can and will have an adverse effect on the combustion process in that cylinder.

Fact: The Fuel Trim Compensation for a bad spray pattern is to increase the fuel contentas the engines EMS sees a weak combustion stroke and believes that it needs more fuel when in fact it has the correct quantity, it's just not atomizing correctly. The cylinder now has excess fuel that is not only adding to the problem, it is now creating additional ones in the process.

Fact: Now the cylinder has excess fuel, this can cause carbon build up on the piston, excess burning on the piston crown, bore wash, gumming, sticking and slow response of any gas recycling valves and components, lacquering of the Lambda Sensor and clogging and damage to the Catalytic Exhaust.

YOU CAN'T FIX WHAT YOU CANT SEE

The problem ALL vehicles EMS's have is that they cannot analyze the injectors spray pattern. The spray pattern of a GDI injector is absolutely critical to the correct running as well as the fuel economy and the emissions.The problem for VM's and EMS manufacturers that there is NO WAY to analyze the injectors spray pattern while it is still on the engine and the compensation actions of the Fuel Trim Program is not beneficial for the long term good of the engine.

Correct analysis of the injectors Spray Pattern is critical to the engines long term performance and should not be an option.

Long Term Engine Damage

There are many reasons why the engines performance slowly deteriorates. Given The driving condition, such as town driving, speed humps, short stop start journeys along with cheap fuel quality, it's only a matter of time before the engine check light comes on and the vehicle needs to go into the workshop for maintenance and repair. CFIS have a greater experience of testing and servicing of aftermarket GDI injectors, including the GDI injector manufacturers like Bosch and Denso. For the likes of Bosch and Denso, the need to check injectors as they were produced the most important requirement for them. They're not concerned if the injector is contaminated by poor quality fuel or if the tip of the injector is covered in carbon and interfering with the spray pattern; that is not a problem with the injector as far as they are concerned, so their testing is to ensure it performs as it was designed.

CFIS low pressure testing can replicate the results of high pressure testing at a reduced level, whilst still achieving the same end results, but in addition it can offer a safer and more detailed examination that the injector manufacturers do not bother with or are not concerned with, but to the driver, they are critical to resolving the issues with the engine’s performance, correctly, efficiently and without the unnecessary replacement of expensive injectors that may only be in need of servicing.

Copyright © 2023 Canadian Fuel Injection Service - All Rights Reserved